Search Results for: switch 海贼王 无尽的世界-【✔️推荐KK37·CC✔️】-靳东童年照-switch 海贼王 无尽的世界gajwi-【✔️推荐KK37·CC✔️】-靳东童年照aw7x-switch 海贼王 无尽的世界5xl02-靳东童年照k10y

The air compressor must be designed to be installed on the apparatus chassis and have a 100% duty cycle. The air compressor shall be an American manufactured, continuous duty, oil-injected type, rotary screw rated up to 150 cfm @ 150 psi. Parts shall be readily available and stocked in the USA with certified service centers in all 50 states. It shall have an additional speed-up gearbox designed and integrally built by the compressor manufacturer. Compressor to have side-by-side gear set to provide for maximum ground clearance. A copy of the certification record shall be included.

The air receiver/separator (vessel) must act as an air/oil separator. The vessel shall be powder-coated carbon steel material and contain an integrated coalescing oil separator element. The vessel must have a lubricant sight glass no smaller than 2” in diameter. The pressure vessel must have a 200 psi (13.8 b) high-pressure relief valve. The vessel must have a replaceable spin-on 25-micron oil filter with safety bypass feature. It must contain an integral, pneumatically piloted blow-down valve. The vessel shall be a horizontal mount design. (A vertical mount air/oil receiver is available as an option.) The vessel shall meet all vessel ASME requirements. Oil carryover is rated 10 ppm or under at full flow.

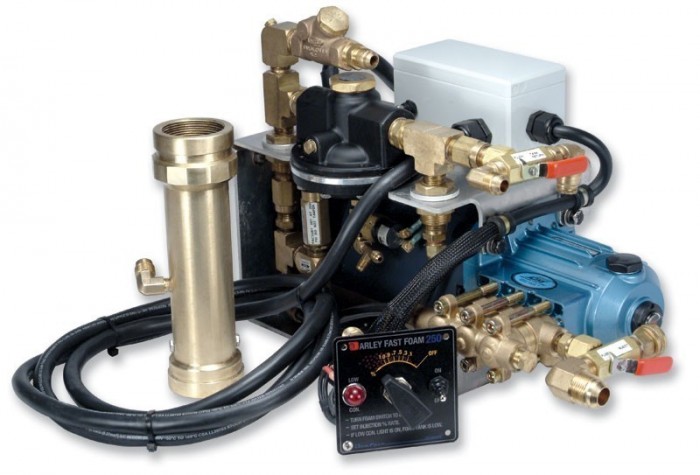

The motor is a 12 VDC, 1/2 hp continuous speed electric motor. The pump is a continuous-duty, piston-type, positive displacement pump. The pump is rated at 1.5 gpm. The pump shall be supplied with a 250 psi (17.2 b) safety relief valve for protection against over-pressurization. The Venturi will flow up to 150 gpm.

Class “A” Foam Proportioner. The Fast Foam system offers a reliable, accurate, compact foam proportioning system at an economical price. This model treats up to 50 gpm @ 1% at pressures up to 175 psi.

Class “A” Foam Proportioner. The Fast Foam system offers a reliable, accurate, compact foam proportioning system at an economical price. This model treats up to 250 gpm @ 1% at pressures up to 175 psi.

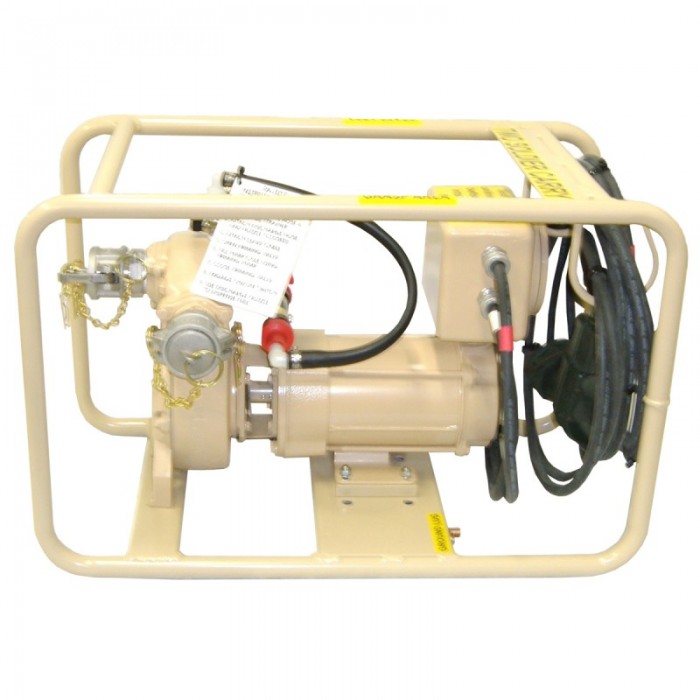

The Darley Foam Refill System is designed to create a safe alternative to refilling your Class A foam tank without the need to climb on top of your truck. The Foam Refill System kit includes all the necessary equipment needed for a simple installation into new or existing apparatus. Once installed, simply attach the pickup hose, insert the tube into the foam pail, hold the switch to on, and fill your foam tank from a safe position until the green foam full light appears on.

This system is offered in two different ways. The panel-mounted kit and the self-contained kit. The panel-mounted kit will come with all the necessary components needed for a simple install. The control panel will be separate from the pump, allowing you to remote mount parts as needed to fit into tighter spaces.

The self-contained kit will include all the same parts as the panel-mounted kit but will be fully assembled with an aluminum bracket to minimize assembly/installation for the end user.

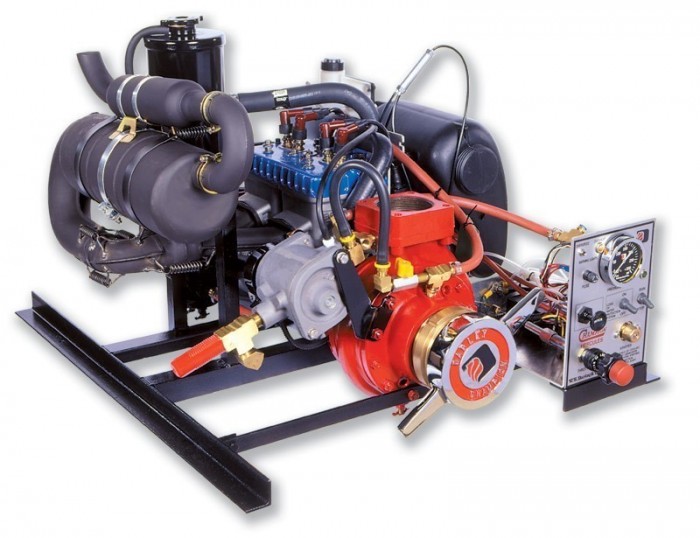

The all-power small-diameter blast hole dewatering system uses the worldwide field-proven dewatering cycle. All functions are hydraulically powered with push-button controls. The unit is self-propelled with a hydrostatic transmission allowing variable speed control. The dewatering head is lowered and raised through the automatic hole guard from the powered reel to the bottom of the blast hole. Push buttons on the control console allows smooth control for this cycle. The pump dewaters the hole, shuts off the head, idles the engine and signals the operator to raise the head and move to the next hole automatically

The rear axle is powered with individual drive hubs allowing disengagement for towing, engagement of both wheels for maximum traction and single-wheel engagement for maximum maneuverability. Moving between blast holes is accomplished by actuating thumb controls on tiller. Hydraulic braking maintains the selected machine position over the hole.

This small-diameter blast hole dewatering system is hydraulically operated and allows dewatering of 2.5 inch or larger holes to a maximum depth of 125 feet. The design of this unit allows for single-person operation. The operator lowers the head through the hole guard to the bottom of the hole. Using the winch on the hole guard, the operator is able to position the head off the bottom hole thus keeping the head from sucking itself into the muck. The pump then dewaters the hole, shuts the head off and signals the operator to move to the next borehole.

One hundred feet of tri-hose allows dewatering of several holes before the power unit needs to be moved. This unit is designed for maximum reliability and will pump abrasives suspended in liquids. The head has no water valves or water seals to leak or plug.